How Cold Chain Products Enhance Food Supply Chain Efficiency

Cold chain logistics is a crucial component in the food supply chain, providing the necessary infrastructure to maintain the quality and safety of perishable products. The complexities of food distribution require that temperature-sensitive goods are stored and transported at controlled temperatures to prevent spoilage and contamination. With the steady increase in the demand for fresh and frozen foods, an effective cold chain not only supports food safety standards but also enhances overall operational efficiency within the supply chain.

Understanding Cold Chain Logistics

Definition of Cold Chain Logistics

Cold chain logistics refers to a temperature-controlled supply chain that ensures the safe storage and transport of temperature-sensitive goods, such as food and pharmaceuticals. It encompasses a series of actions and infrastructure designed to maintain the required low-temperature environment from the point of origin to the final customer. This process includes refrigerated storage, temperature-controlled transport, and the monitoring of conditions throughout the distribution process, crucial for preserving the integrity of products that could degrade if exposed to improper temperatures.

Importance of Cold Chain in Food Supply

The importance of the cold chain in the food supply cannot be overstated. It plays a vital role in minimizing food waste by maintaining the quality and safety of perishable items throughout the distribution network. With an effective cold chain, businesses can ensure that fruits, vegetables, dairy products, meats, and other perishable goods retain their freshness and nutritional value, ultimately benefiting consumers as well. Moreover, a well-implemented cold chain system is essential for compliance with food safety regulations, thereby protecting public health and enhancing consumer trust in food products.

Benefits of Implementing Cold Chain Products

Reduction in Food Spoilage and Waste

Implementing robust cold chain products leads to a significant reduction in food spoilage and waste. By ensuring that perishable goods are stored and transported under optimal conditions, businesses can avoid the economic losses associated with unsold, spoiled inventory. This efficiency not only supports higher profit margins but also has positive implications for environmental sustainability, as it reduces the overall amount of food discarded. By minimizing waste, companies can contribute to a more sustainable food system.

Prolonged Shelf Life of Perishable Goods

The proper implementation of cold chain solutions prolongs the shelf life of perishable goods. Products that are consistently kept at ideal temperatures show extended viability, allowing businesses to maintain stock for longer periods and respond flexibly to market demands. This capability is particularly important in the context of unexpected fluctuations in consumer preferences or supply disruptions. Enhanced shelf life ultimately translates to greater economic efficiency, benefiting producers, retailers, and consumers alike.

Challenges in Cold Chain Management

Maintaining Consistent Temperatures Across the Supply Chain

One of the primary challenges in cold chain management is ensuring that temperatures remain consistent throughout the product lifecycle. Variability in temperature can occur at various points, from storage facilities to transport vehicles. These fluctuations may lead to spoilage, which undermines the safety and quality of food products. Therefore, maintaining a stable temperature is essential, requiring proactive measures such as regular monitoring and updates to equipment to ensure efficiency and compliance with health regulations.

Additionally, different products may require specific temperature controls, making it crucial for logistics managers to understand the unique needs of each item in the cold chain. Proper staff training and an emphasis on adherence to protocols are also essential factors for achieving consistent temperature maintenance. Implementing real-time tracking technologies not only assists in monitoring temperatures but also serves as a preventive measure against potential crises.

Handling Emergencies and Equipment Failures

Emergencies, such as equipment failures or sudden weather changes, pose significant risks to cold chain integrity. When refrigeration units fail or transport vehicles experience breakdowns, perishable goods can face immediate temperature threats. Organizations need to develop contingency plans that include backup equipment, predefined emergency protocols, and quick access to additional resources. These mitigation strategies are instrumental in preventing losses and maintaining uninterrupted service levels across the supply chain.

Furthermore, regular equipment maintenance and timely upgrades are vital components of reducing the likelihood of malfunctions. Incorporating redundancy within the cold chain infrastructure ensures that organizations can quickly respond to unforeseen challenges. The establishment of effective communication channels among team members also enhances readiness, promoting swift actions that minimize potential damage during emergencies.

INTCO Healthcare: A Leading Provider of Healthcare Solutions

Overview of INTCO Healthcare

History and Mission

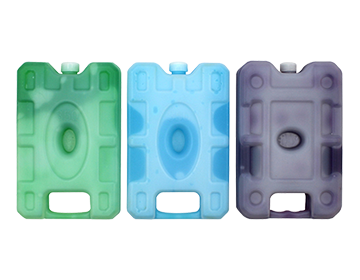

Founded with the mission of improving healthcare accessibility and safety, INTCO Healthcare has emerged as a key player in the cold chain sector. The company is capable of producing cold chain products including ice packs, ice boxes, and cartoon ice packs. These products are used for food transportation, pharmaceutical shipping, and preserving food during outdoor activities. Their commitment to maintaining high standards reflects a deep understanding of industry requirements, emphasizing both product efficacy and consumer safety in cold chain management.

INTCO Healthcare’s expansive journey has included significant investments in research and development, thereby enhancing its pioneering capabilities in cold chain technologies. As the organization continues to evolve, its strategic focus on sustainability and efficiency resonates at every level, culminating in solutions that bolster both public health initiatives and business operations.

Key Products and Services

INTCO Healthcare offers a wide range of products and services designed to enhance cold chain management. These include temperature-controlled packaging solutions and temperature-sensitive shipping options that cater to the specific needs of healthcare providers and logistical operators. Their innovative products ensure that a comprehensive approach is employed to maintain the integrity of medications and vaccines throughout the distribution process.

Furthermore, by leveraging state-of-the-art technology and focusing on user experience, INTCO Healthcare is positioning itself as a key partner for businesses navigating the increasingly complex landscape of cold chain solutions.

Contribution to Efficient Cold Chains

Innovative Solutions by INTCO Healthcare

INTCO Healthcare‘s contribution to efficient cold chains is invaluable. The company has made it possible to achieve real-time visibility of temperature-sensitive goods. These innovations enable businesses to respond swiftly to temperature fluctuations, thus reducing waste and maintaining product integrity.

Moreover, INTCO’s development of specialized insulation materials furthers its commitment to sustainable practices. These advanced materials decrease energy consumption while maintaining stable temperatures, a win-win for both economic efficiency and environmental responsibility. By continuously exploring new technologies and methodologies, the company reinforces its role as a leader in enhancing cold chain logistics in the healthcare and food sectors alike.

Future Trends in Cold Chain Technology

Growth of Sustainable Practices

As the global marketplace continues to evolve, sustainability is becoming increasingly integral to cold chain management. Organizations are recognizing the financial and environmental benefits associated with adopting sustainable practices, such as utilizing energy-efficient systems and minimizing waste. The growth of eco-friendly technologies reflects a collective commitment to reducing carbon footprints across the supply chain, thereby fostering a more sustainable future.

The use of biodegradable packaging materials and sustainable refrigeration systems enhances overall efficiency while supporting compliance with international regulations. As consumers become more environmentally conscious, companies that prioritize sustainable cold chain practices may also experience increased brand loyalty and competitiveness in the marketplace.

Conclusion

INTCO Healthcare stands out for its innovative cold chain solutions, which are essential for maintaining the integrity of temperature-sensitive goods. Furthermore, the industry recognition is reflected in awards received for innovative technology solutions, solidifying INTCO as a leader in the cold chain sector. As the company continues to evolve and adapt to market demands, its focus on customer success and sustainability keeps them at the forefront of enhancing food supply chain efficiency through cold chain products.