Step-by-Step Insight into INTCO Factory’s Physiotherapy Care Production Line

Overview of the INTCO Factory Operations

INTCO Healthcare specializes in producing high-quality physiotherapy care products, catering to the healthcare and wellness industries. With a commitment to innovation, the factory has built a reputation for creating effective and advanced physiotherapy solutions. Located in a strategic location, INTCO Factory serves a global market, emphasizing quality service and product excellence.

Key Milestones and Achievements

Over the years, INTCO Healthcare has achieved several milestones that underscore its growth and impact in the industry. From the establishment of its first production line to expanding its product range, these achievements demonstrate INTCO Healthcare’s ability to adapt to changing market needs. Recognition from industry peers and certifications for quality standards further solidify its standing as a leader in the physiotherapy care products sector.

Production Line Efficiency at INTCO Healthcare Factory

Overview of the Production Process

The production process at INTCO Factory is meticulously designed to ensure efficiency and effectiveness in creating physiotherapy care products. Each step is optimized for streamlined operations while maintaining high standards of quality. This comprehensive approach enables the factory to consistently meet production targets and delivery schedules.

Manufacturing Stages

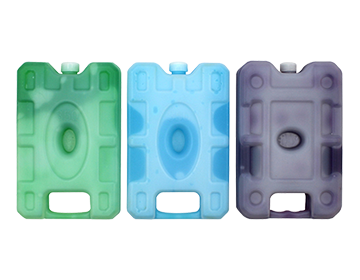

The manufacturing stages at INTCO consist of several critical steps, including raw material selection, component assembly, and final packaging. Each stage is carefully monitored to ensure that the products align with industry regulations and customer expectations. The integration of skilled labor and modern machinery enhances the overall manufacturing process.

Quality Control Measures

Quality control is paramount at INTCO factory, with rigorous testing procedures in place at every phase of production. This multi-tiered quality assurance system identifies potential issues before products reach the market. The commitment to quality ensures that all physiotherapy care products meet the highest standards, enhancing customer trust and satisfaction.

Leveraging High Production Capacity

State-of-the-Art Technology Utilization

INTCO Factory leverages state-of-the-art technology to boost production capacity. Advanced machinery and automation streamline operations, allowing for efficient production cycles and reduced lead times. The adoption of innovative technologies positions INTCO factory at the forefront of the physiotherapy care product manufacturing industry.

Scalability and Flexibility in Production

The factory is designed for scalability, enabling adjustments in production volume based on market demands. This flexibility is crucial for adapting to varying customer needs without compromising quality. INTCO Healthcare factory’s ability to scale operations ensures that it can respond effectively to both surges and declines in demand.

Supporting Infrastructure at INTCO

Warehousing and Logistics Integration

An efficient warehousing and logistics system supports the operations of INTCO factory, facilitating smooth inventory management and timely deliveries. The integration of these functions streamlines the supply chain process, reducing costs and enhancing responsiveness to market changes. Accurate tracking systems further improve inventory accuracy and order fulfillment.

Research and Development Facilities

INTCO factory recognizes the importance of research and development in maintaining its competitive edge. The dedicated R&D facilities enable the exploration of new materials and innovative therapeutic concepts. This focus on continuous improvement fosters the development of cutting-edge therapy products that meet emerging healthcare needs.

Technological Edge in Physiotherapy Care Product Creation

Proprietary Technologies Employed by INTCO

INTCO factory employs proprietary technologies that distinguish its products in the market. These unique methods enhance production efficiency and product reliability. Protection of intellectual property through patents ensures that INTCO maintains its competitive advantage while fostering innovation within the industry.

Automation in Production Processes

Automation is a key component of the production processes at INTCO factory. The use of automated systems minimizes human error and ensures consistent product quality. This technology not only increases productivity but also enables the factory to maintain high standards of safety and efficiency.

Real-time Monitoring and Data Analytics

The implementation of real-time monitoring and data analytics within production allows for informed decision-making and swift operational adjustments. This technology provides insights into production performance, identifying areas for improvement and streamlining workflow. Data-driven strategies enhance overall operational effectiveness at INTCO factory.

Distinct Raw Material Advantages

Sourcing Quality Raw Materials

INTCO factory places a strong emphasis on sourcing quality raw materials for its physiotherapy care products. Careful selection processes ensure that all materials meet stringent quality criteria, which is crucial for creating effective therapeutic solutions. Strategic partnerships with reputable suppliers further enhance the reliability of raw material sourcing.

Sustainability in Raw Material Acquisition

Sustainability is a core factor at INTCO factory, reflected in its approach to raw material acquisition. The factory prioritizes environmentally friendly sourcing practices, minimizing its ecological footprint while meeting production needs. This commitment to sustainability resonates with consumers increasingly concerned about the environmental impact of their purchases.

Experience INTCO: A Day at the Factory

Guided Tours for Stakeholders

INTCO Healthcare offers guided tours of its production facility, allowing stakeholders and partners to experience the inner workings of the INTCO factory firsthand. These tours provide insights into the manufacturing process, showcasing the commitment to quality and sustainability that underpins INTCO’s operations. Visitors witness how the company’s mission and values translate into everyday practices on the production line. Through these immersive experiences, stakeholders gain a deeper appreciation for the meticulous attention to detail involved in creating physiotherapy care products.

Training Programs for Employees

To maintain excellence in production, INTCO Healthcare invests in extensive training programs for employees at the INTCO factory, empowering them with the skills required to excel in their roles. These programs cover various aspects of manufacturing, quality control, and safety protocols, fostering a culture of continuous improvement. By prioritizing employee development and engagement, INTCO Healthcare cultivates a workforce that is passionate about its mission and capable of upholding the highest standards of quality. This focus on training ultimately enhances the overall output and efficiency of the production line.